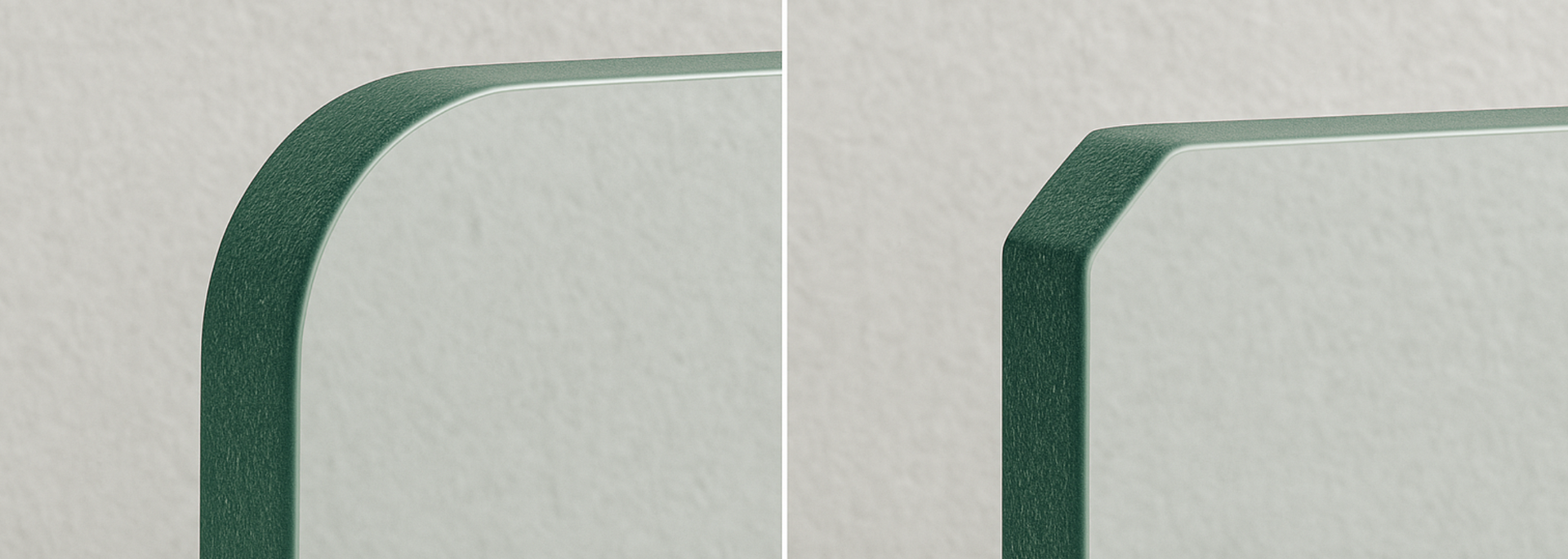

Toughened glass: radius vs dubbed corners

Share this blog:

Toughened glass corners can be finished with a radius or dubbed corner. Discover the differences today.

To the untrained eye, one piece of toughened glass looks much like another.

Of course, some glass products have defining visual features: coloured glass, for instance, or glass with a textured interlayer. But often, a piece of glass is, well, a piece of glass.

To the trained eye, however, there are small but significant differences between glass products. In the world of glass manufacturing, the devil is in the details. Quality isn't immediately obvious – but it's there all right, manifested in a thousand details.

One example of this is the way the corners are finished.

Toughened glass – our speciality – can be finished with either radius or dubbed corners.

Both of these methods soften the 90-degree corners of a piece of toughened glass. In both cases, this makes them safer to handle and arguably better to look at.

But they're used for different thicknesses of glass (a key consideration in building regulations) and have subtly different appearances.

So, what are those differences? Let's find out.

What are the differences between radius and dubbed corners?

Dubbed corners have a sanded-down look. Radius corners, by contrast, have a rounded edge. This makes radius corners a preferred choice for table tops and other pieces of furniture that could be touched by children or vulnerable adults.

Dubbed corners can be added to glass of any thickness. Radius corners, however, can only be applied to glass with a thickness of six millimetres or over.

They're also manufactured in different ways. Dubbing is a manual process where a dubbing pad is used to sand down the corner. Radius corners are made by cutting the corners along a circular arc. This can be done with specific tools or CNC machines.

What other kinds of glass corners are there?

Radius and dubbed corners are just two kinds of corners found on safety glass products.

Pencil polish edgework – also known as "diamond edge", "crown edge", "semi-round edge" and "half-moon edge" – is a type of glass corner that has the rounded edges of a pencil eraser. It's used for shelves, tabletops, car windows and more.

Bevelled corners are angled or "chamfered". This makes the corners slope rather than cut off abruptly. Like radius and dubbed corners, they're used to soften edges and to make glass products more aesthetically appealing.

We discuss other kinds of edgework (which has an impact on glass corners) in our

glass edgework guide.

Which type of corner should I choose for my project?

The choice between radius, dubbed and other kinds of glass corners depends entirely on the project in question. If in doubt, your best bet is to consult a

glass processor. They'll be able to talk you through your options and make recommendations.

Are you looking for high-quality

toughened glass panels? Want the corners to be smoothed or customised in a different way?

Get in touch with ToughGlaze today for a quick, competitive quote.