Safety glass vs regular glass: key differences explained

Share this blog:

What are the most important differences between safety glass and regular glass? Let's dig into the details.

Glassmaking is an ancient industry. But the last couple of centuries have seen great strides in one particular direction: the invention and manufacturing of safety glass.

Safety glass, as the name suggests, is glass that's been manufactured for extra safety. It achieves this in two ways. First, the glass is harder to break than regular glass. And secondly, it breaks in special ways.

There are two main types of safety glass –

toughened glass and

laminated glass.

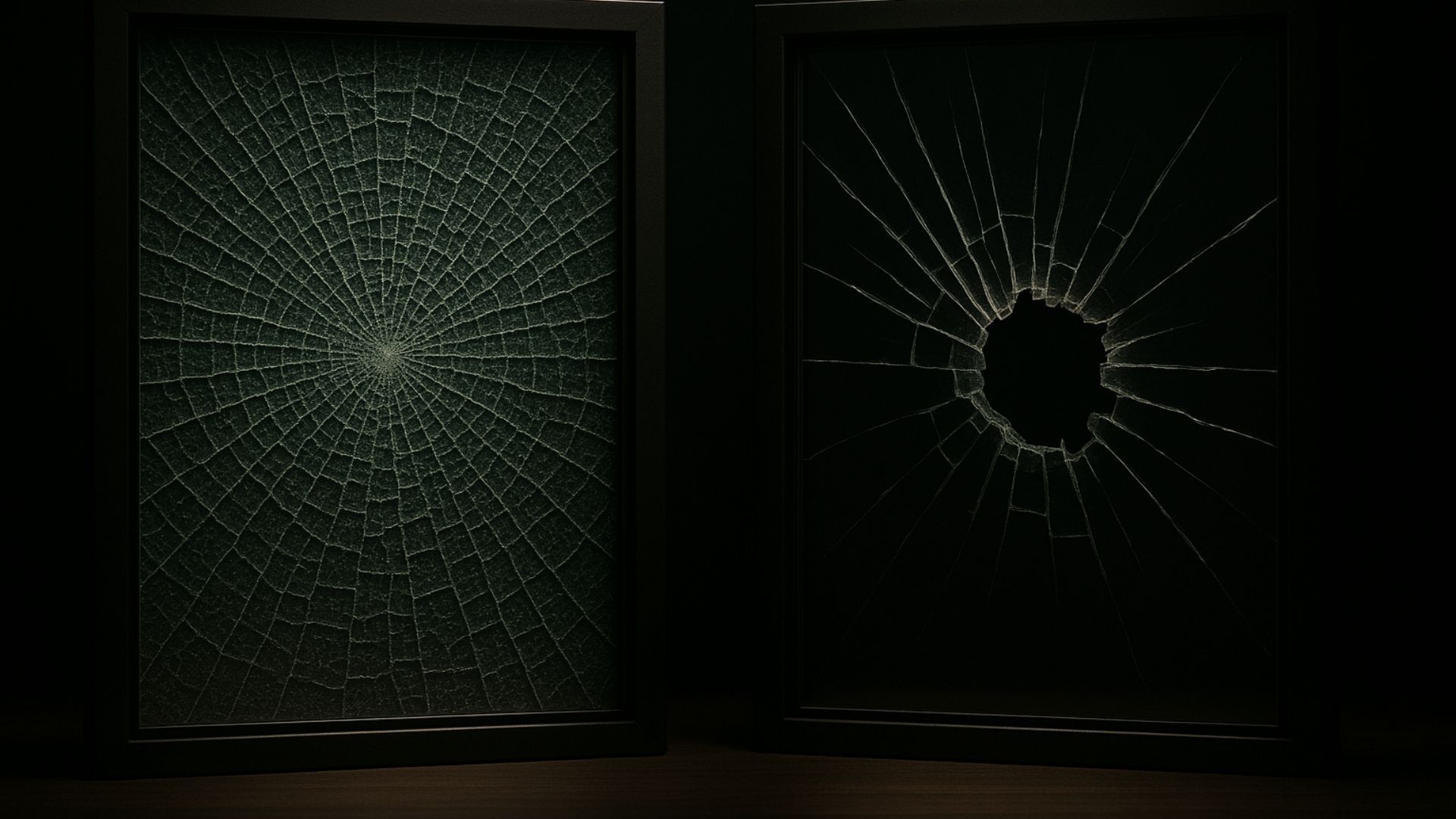

Toughened glass is around five times stronger than regular glass. When it breaks, it breaks into lots of tiny, relatively harmless pieces rather than dangerous shards.

Laminated glass, meanwhile, is multi-layered. When it breaks, the glass stays in the frame. This makes it ideal for situations where the glazing needs to withstand manual force or extreme weather.

Those are the headlines. But what are the other differences between safety glass and regular glass? And what other types of safety glass are there?

Strength

As you might expect, safety glass is much stronger than regular glass. Both toughened glass and laminated glass are around five times stronger than their annealed equivalents.

In the case of toughened glass, this is because of the treatment process. The high temperatures used make the finished product more resistant to impact and thermal shock.

By contrast, laminated glass gets its strength from its multi-layered structure and the way the outer panes bond to the plastic interlayer.

Applications

Another key difference between regular glass and safety glass is where it tends to be applied.

In some situations, safety glass has to be used in order to be compliant with building regulations. This is the case in "critical locations". The details are complex, but the basic point is that a location is critical if the glass could cause serious harm and injury when it breaks and falls.

Safety glass, then, is often used for low-level windows, door glazing and structural glazing such as balustrades, glass stairs and glass floors. It's also used in shower screens, tables and worktops.

Laminated glass has a couple of specific use cases. First, it's used on vehicular windscreens. This is so that the glass won't fall on the driver or pilot if the glass breaks.

Secondly, it's often used for glazing in areas prone to hurricanes and other extreme weather. In these applications, laminated glass can spell the difference between life and death.

Other uses of laminated glass include aquariums, animal enclosures and cabinets for precious objects, whether in boutique shops or museums. Meanwhile, toughened glass is used for oven doors, kitchen splashbacks and smartphone screens.

How can you identify safety glass?

The most straightforward way to identify safety glass is to look for a safety glass marking. This will be next to the name and logo of the manufacturer.

In the UK, these safety glass markings reflect the British Standard (BS). The standard for toughened glass is BS EN 12150. For laminated glass, it's BS EN 14449.

Occasionally, designers and building owners ask for these markings to be removed. In this case, there are a few other ways to identify whether a pane of glass is safety glass or regular glass.

First, there's the rub test. Toughened glass has smoother, more rounded edges than its counterparts. You might also spot dimples, tiny scratches or signs of warping and bending. These are byproducts of the manufacturing process.

Finally, you can look at the glass through a pair of polarised sunglasses. These are designed to reduce glare and protect the wearer's eyes from UV rays. They will also reveal dark patches or lines on a pane of toughened glass – but never on regular glass.

What other types of safety glass are there?

Toughened and laminated glass can be further customised to suit specific use cases. For instance, it can be manufactured to meet fire ratings. This is where an interlayer – in our case,

made out of a special gel – slows down the spread of fire. The idea is that this gives people more time to evacuate and the emergency services longer to arrive.

These two main kinds of safety glass can also be made blast-resistant, bandit-proof and bullet-resistant. The glass is strengthened to make it withstand even greater types of force than standard safety glass. Bandit-proof glass is also known as security glass.

What's the difference between safety glass and security glass?

In the context of architecture, safety and security are the same thing, right? Not when it comes to types of glazing.

Safety glass is manufactured to minimise injury from accidental breakage. This is why it has to be used in "critical locations". It's all about the safety of passersby, residents and building users.

Security glass, by contrast, is manufactured to resist deliberate attacks – "bandits, bombs and bullets", to use an industry phrase. It's made from laminated glass but given thicker interlayers to withstand greater impacts.

When was safety glass invented?

What does safety glass have in common with Braille, the parachute and the stethoscope? Answer: they were all invented in France!

Toughened glass was invented in the late 19th century by François Barthélémy Alfred Royer de la Bastie. The earliest examples were made by quenching near-molten glass in a heated bath containing either oil or grease.

Laminated glass, by contrast, was invented by the chemist Édouard Bénédictus. It was an accidental discovery. If you're interested in learning more, check out our blog post on

who invented laminated glass.

Since then, new ways to treat and customise safety glass have been pioneered and put into practice. The basic materials, however, are pretty much unchanged. To François and Édouard we say "Merci beaucoup!"

ToughGlaze is a trusted glass processor based in Bedford, UK. Do you need high-quality

safety glass for a project? Don't hesitate to

get in touch for advice or to request a free quote.