Nickel sulfide inclusions in toughened glass: a simple explainer

Share this blog:

Nickel sulfide inclusions in toughened glass can sometimes lead to spontaneous breakage. In this article, we look at the phenomenon and how to stop it.

In February 2023, it was reported that multiple windows had spontaneously shattered in San Diego's central courthouse.

This wasn't the work of a vengeful ghost seeking justice. It wasn't even because of damage to the glass during the handling or glazing process.

It was, in fact, the result of a barely perceptible imperfection in the glass – the presence of nickel sulfide inclusions.

These imperfections are so small that it's hard to believe they can cause spontaneous shattering. But like the straw that broke the camel's back, they have the power to cause damage without warning.

In this article, we take a look at these inclusions and how best to prevent them.

What are nickel sulfide inclusions?

Nickel sulfide inclusions are a byproduct of glass manufacture. They only become a problem after the tempering process.

Toughened glass is made by heating and then rapidly cooling glass. The purpose of this is twofold: to strengthen the glass and change the way it breaks. Unlike standard annealed glass, toughened glass breaks into hundreds of small pieces – not big jagged shards that can cause injuries.

Nickel sulfide inclusions are pebble-like objects that are so small as to be barely perceptible.

But over time, these imperfections can expand – and in some rare cases, cause enough tension in glass that it shatters. This doesn't happen in normal glass – only toughened glass.

That's because

toughened glass is already under tension as a result of the tempering process. This is what makes it so robust in most everyday situations. Counterintuitively, however, those tiny expanding "pebbles" are enough to push it over the edge.

You can tell if the breakage was due to a nickel sulfide inclusion because of its characteristic "butterfly" pattern.

It's important to emphasise that these breakages are rare. One estimate puts it as one breakage per 400 tonnes of toughened glass

But just because it's rare doesn't mean it's unimportant. Aside from being frightening, a spontaneous breakage leaves the customer out of pocket. That's why companies like us take it seriously and use a process called "heat soak testing" to stop it as much as possible.

How can you prevent nickel sulfide inclusions?

At the time of writing, there's no known technology that entirely eliminates the formation of nickel sulfide inclusions during the manufacturing process. But there is a method for detecting them once the glass has been tempered – heat soaking, or "heat soak testing".

This is where the finished pane of toughened glass is put inside an oven and heated to 290°C (554°F) for several hours. If a nickel sulfide inclusion is present, the glass will break in the oven. It's a way of detecting faulty glass before it gets installed.

In the case of the courthouse in San Diego, "the original specifications for the $550 million building called for heat soaking but that was not done". Skimping on this process, then, can have costly consequences.

That said, heat soaking isn't completely infallible.

Some studies have suggested that it detects around 95% of flawed panes, although it's unclear how you would know the process had failed until the breakage occurred much later on.

Another drawback of the test is that it increases both costs and lead times. But there are two good reasons to go ahead with the process. First, spontaneous breakage is dangerous, frightening and expensive. Second, it's not possible to detect nickel sulfide inclusions any other way.

Does heat soak testing mean that toughened glass will never break?

No – toughened glass can still spontaneously break even after heat soak testing. There are two reasons for this.

First, heat soak testing doesn't guarantee the complete elimination of all nickel sulfide inclusions.

And second, there are other reasons for toughened glass to spontaneously break such as thermal stress – where there's a notable difference in temperature between the edge and centre of the glass – and minor damage to the edges caused during manufacturing or transportation.

Frames can also cause spontaneous breakages. When temperatures change, the glass will expand and contract. If there isn't enough space between the frame and the glass to accommodate these changes, the resultant stress can cause the glass to shatter.

In short, you can never be 100% sure that your toughened glass won't suddenly shatter – but by heat soak testing it, you remove one possible cause.

Do nickel sulfide inclusions affect other types of glass?

Nickel sulfide inclusions only affect thermally tempered glass, not "normal" (annealed) glass. However, you can't use this in contexts where safety glazing is required.

ToughGlaze and heat soak testing

At ToughGlaze, we take nickel sulfide inclusions seriously – not only because spontaneous breakage can give you a fright, but also because replacing toughened glass costs money. It may be rare, but it's not worth the risk.

That's why we offer heat soak testing using the international testing method BS EN 14179 -1: 2016.

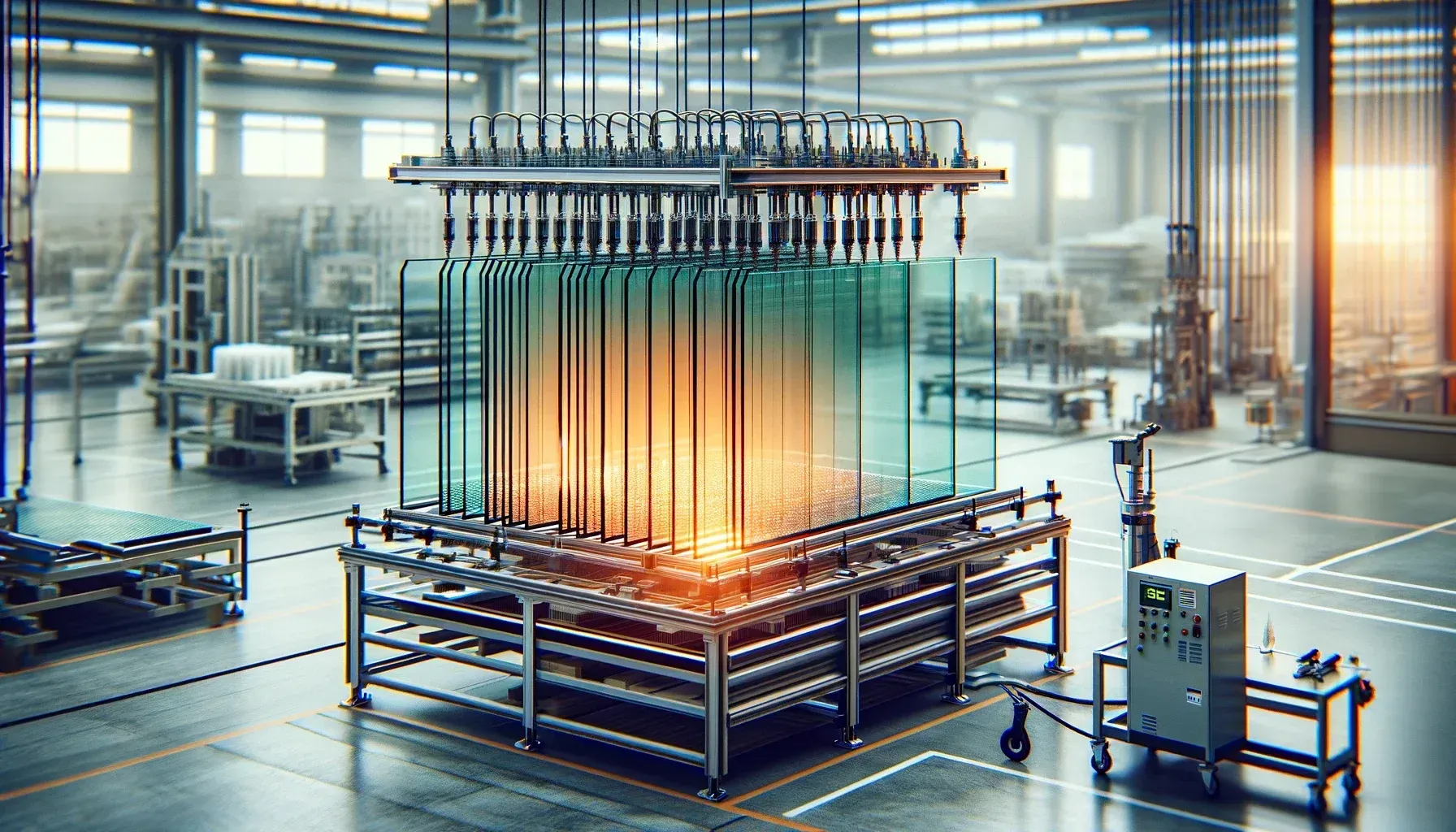

The process goes something like this. After the individual glass panels have been toughened, they're placed on special racks inside a calibrated oven.

The glass is then heated for two hours and stabilised at around 290°C (554°F). The panes stay at this temperature for another two hours and then cool down over a couple more. If anything breaks in the oven then the pane gets replaced and the process starts over.

It's not guaranteed to detect nickel sulfide inclusions and it won't make the glass indestructible – but it does reduce the likelihood of one possible cause of spontaneous breakage.

Heat soak testing is worth doing for all toughened glass panels, but especially if the glass will be inaccessible or hard to access after installation – if it's fitted high up, for instance.

The bottom line

Our approach to nickel sulfide inclusions and heat soak testing is one reason why you can count on us for a thorough, reliable service.

Although spontaneous breakage is rare, we believe it's worth reducing the risk. The extra time and cost are a way of future-proofing your installations.

Do you need toughened glass for a project? At ToughGlaze, we cut, process and dispatch our glass from one state-of-the-art facility – so you save time, hassle and money. We also offer

heat soak testing to help ensure long-lasting integrity and protect your investment. Interested?

Get in touch with one of our friendly experts today.