How glass wheel cutters work

Share this blog:

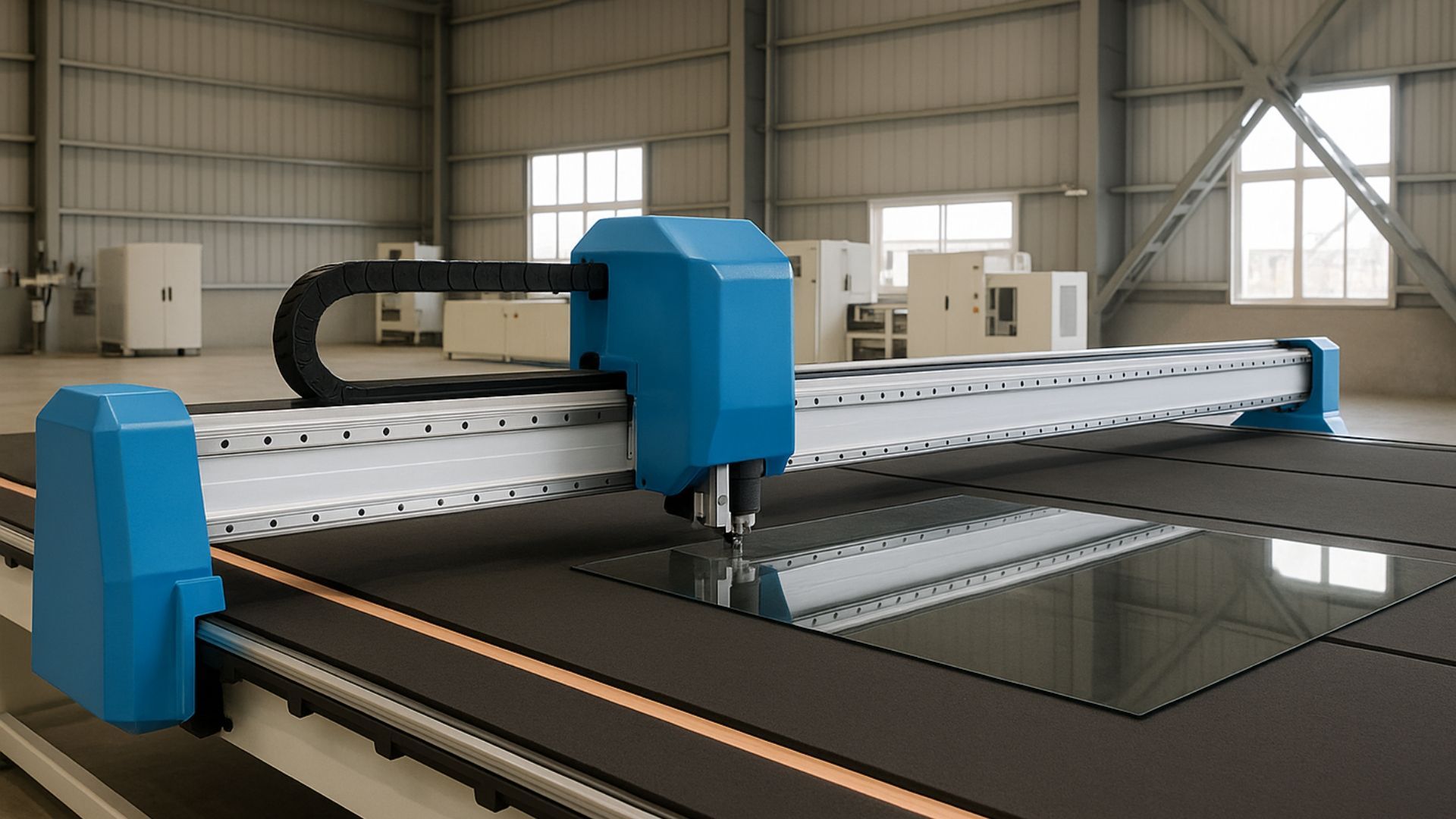

Many glass manufacturers use wheel-cutting machines to cut their glass. Find out how the process works in our guide.

How do you cut glass? It's a question we've explored in depth in another of our blog posts. The answer is perhaps more complex than you'd expect.

If you want to cut a material, use a blade. Right? Half-right. Yes, glass is cut with blade-like wheels, whether manually or by a machine, but it's also cut with pressurised water and even lasers.

While these methods are all used in the glass fabrication industry, glass wheel cutters are the most common. Since the 19th century, manufacturers have been cutting glass with manual wheel cutters – but in today's modern marketplace, more and more manufacturers use machines to do the job.

A manual glass cutter is a handheld tool used to score and snap glass. A mechanical glass wheel cutter looks more like a giant paper guillotine. But where a paper guillotine has a blade, a glass wheel cutter has a wheel. This passes across and incises the glass.

At first glance, you might think that glass cutting is an imprecise art. In fact, the technology has developed to such an extent that even thin pieces of glass can be cut by a mechanical wheel.

Perhaps the only drawback of glass wheel cutting is that it tends to chip the product. This isn't a problem for the customer – only for the supplier who has to fix the chipped glass with extra processing.

How they work

A manual glass wheel cutter is a handheld tool with a wheel at its tip. This is usually made from hardened steel or tungsten carbide – both tough as nails.

Many also have a small oil reservoir. This lubricates the wheel as you go and means that, when you come to snap the glass, the line is smooth and clean.

But before the glass can be snapped, it must be scored. Glass processors often use a table edge or ruler to score the glass. The glass itself should be laid on a soft material. Cardboard, towel and cork can all help protect the glass from scratching.

The worker, too, needs protection. This usually takes the form of protective personal equipment (PPE): gloves, safety goggles and a face mask.

Mechanical glass wheel cutters also have super-tough wheels. In the case of machines, they're sometimes made of diamond instead of tungsten carbide.

The machine is usually computer-operated, although older models are operated by buttons. The wheel passes across the glass and scores the surface.

The wheel itself doesn't cut the glass. Instead, it weakens the surface tension, making it ready to be snapped.

As with manual wheel cutting, the amount of pressure is critical. Go easy on the glass and the score will be messy. Apply too much pressure and the break will be raggedy. Modern machines regulate the amount of pressure applied and, like their manual counterparts, lubricate the wheel with oil.

Once this incision is made, the glass is snapped. Smaller pieces are snapped by hand, while larger pieces are snapped using the machine's breaking mechanism.

A brief history of glass wheel cutting

Glass wheel cutters, as we know them today, originated in the 19th century.

Samuel Monce of Connecticut, USA, developed the first glass wheel cutter for flat glass in 1869. This is the prototype for today's machines, and was a pivotal innovation in the history of glass manufacturing.

But while the handheld wheel cutter is less than 200 years old, wheels have been used to cut glass for decoration since the days of Ancient Rome.

In the first century AD, for instance, historian Pliny the Elder describes the use of a rotating stone wheel to cut patterns into glass.

Centuries later, 18th-century English and Irish glassmakers used wheel cutting to create items such as chandeliers and vessels. By the end of the century, these were powered by steam for extra efficiency.

But while wheels were used to cut glass for decorative purposes, they were only used to cut flat glass in the late 19th century. Before then, glass was cut in a range of different ways.

Before the 14th century, glass was scored with a hot iron rod and then cracked along the score line.

Between the 14th and 16th centuries, manufacturers began using diamond-tipped cutters. These offered much greater precision than hot iron rods – though still not a patch on today's machines.

Despite the advent of the manual glass wheel cutter, manufacturers used diamond-tipped hand tools to score large sheets of glass until the early 1900s.

The main advantage of the glass wheel cutter is clear. Whereas rods and tipped hand tools did the job, they were far from efficient. Glass makers had to score the glass bit by bit. By contrast, a glass wheel cutter could be run through the glass like a guillotine or lawnmower.

What's better: glass wheel cutting or water jet cutting?

Glass wheel cutting is far from the only way to cut glass. Manufacturers often use a method called "water jet cutting". This involves shooting a high-pressure jet of water mixed with an abrasive substance at the glass.

This isn't just a gentle dousing. This is high pressure – and it can cut metal and concrete, as well as glass.

Whether a manufacturer chooses glass wheel cutting or water jet cutting depends on the type of glass being cut, its thickness and the level of precision required.

Broadly speaking, water jet cutting is best for intricate shapes and can handle brittle and heat-sensitive materials. Wheel cutting is faster and works best for simple, straight cuts on thinner pieces of glass.

As a customer, the precise method used shouldn't affect the end product. It's best to look for marks of quality rather than particular techniques.

Are you looking for high-quality toughened or laminated glass? At ToughGlaze, we supply a wide range of products, all built in line with British standards. Get in touch today for a quick, competitive quote – or explore our rangeonline.