The science of silence: how soundproofing glass works

Share this blog:

What is soundproofing glass? And how does it work? Learn all about acoustic glass in our 5-minute guide.

"Silence is golden", they say. But in today's traffic-heavy, fast-moving world, it's rarer than the purest platinum.

This can be a problem.

It's a problem, of course, for those unfortunate folk who happen to live close to airport runways. As those great metal birds descend from the heavens, they belch out some seriously powerful sound waves.

At 1,000 feet, a large jet plane can deliver as much as 85 ear-splitting decibels to those on the ground. Eighty-five decibels is the threshold for causing hearing loss with prolonged or repeated exposure.

So, yes. That's a problem.

But airports aren't the only noise polluters. Excessive sound levels are also a problem for people in urban areas, where the honks, growls and thrums of traffic coalesce into an irritating cacophony. According to UK government research, 40% of all adults in England are exposed to regular road traffic noise

in excess of 50 decibels.

Outside of the home, there are practical and security-related concerns that stem from excessive noise or sound egress. Take, for instance, the recording studio that needs to capture pounding drums in one room and a wailing guitar solo in another – or the office boardroom where powerful people discuss commercial secrets in earshot of all and sundry.

It's a problem. But where there's a problem, you can count on some smart folk to come up with clever solutions.

One such solution is acoustic – or "soundproof" – glass.

In this guide, you'll learn what acoustic glass is and how it works.

What is soundproof glass?

Let's make one thing clear from the start.

There really is no such thing as "soundproof" glass – at least if we're being technical about it.

This is for two reasons.

First, no glass is truly soundproof. A good "soundproof" glazing system will do a stellar job of keeping noise out – or in. But it won't curb it completely.

For this reason, soundproof glass is more properly called "acoustic glass", "sound-absorbing glass" or "noise-reducing glass".

Second, an acoustic glass panel – on its own – is about as useful as a velvet cheese grater. For acoustic glass to be effective, it must be used with an equally "soundproof" framing system.

So. Acoustic glass is a special type of glass that can drastically reduce noise levels when combined with a suitable frame.

It achieves this in four ways.

How does acoustic glass work?

1. The glass itself absorbs sound

This might be hard to believe if you live under a Heathrow flight path, but trust us – it's true.

Glass is pretty good at curbing noise. Or, to put it another way, it's a bad sound conductor.

This is because glass is a fairly rigid and inflexible material. Sound waves travel freely through the air because air moves the way sound waves want it to. When confronted with the solid, inflexible reality of glass, most sound waves simply bounce off.

The problem is that most residential and commercial glazing is relatively thin. The thinner the glass, the more it vibrates – and the more it vibrates, the more sound waves get through.

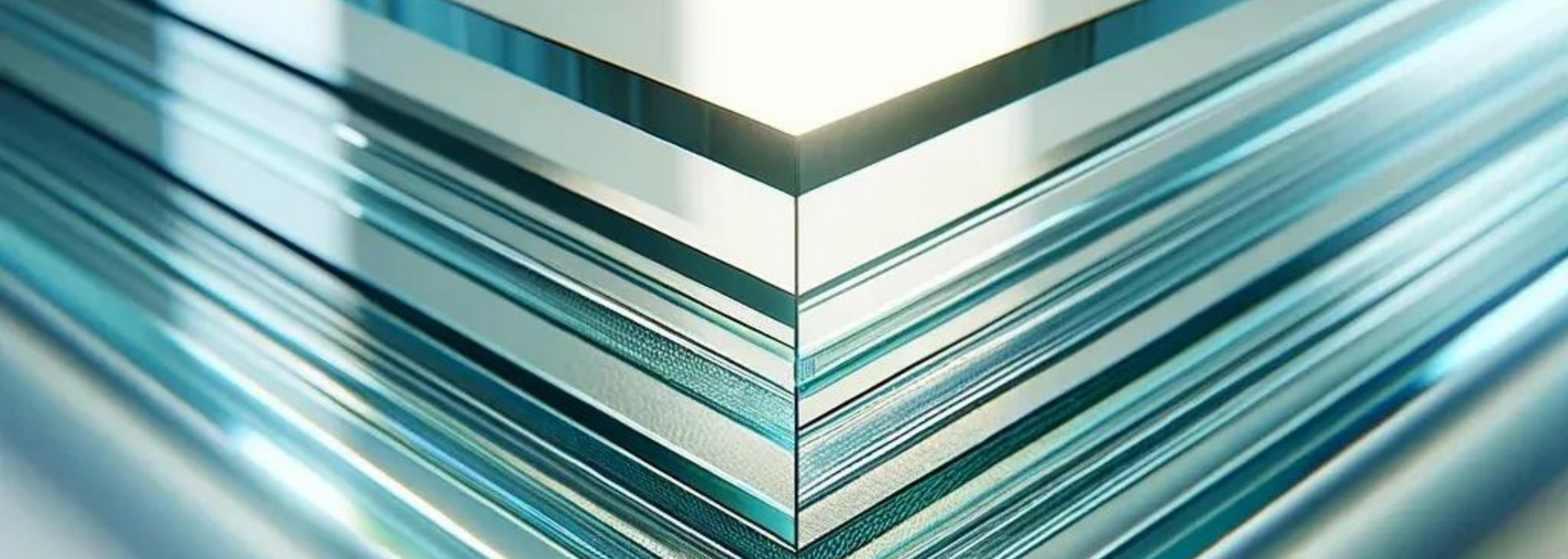

That's why we use laminated glass for sound control. Laminated glass is, effectively, two panes of glass that have been firmly glued together to make one thick pane.

TG AG, our acoustic glass, can be anywhere from 9.5 millimetres to 60 millimetres thick. To put that into perspective, most residential double-glazing panels are four millimetres thick – or less.

Thicker glass means more mass. And more mass means less vibration and less sound ingress. Simple.

2. Special interlayers absorb sound

As we've seen, laminated glass is like a glass sandwich. It consists of two or more panes joined with polymer interlayers.

In acoustic glazing, these interlayers aren't just there to glue the glass together. They, too, can play a part in reducing noise.

Our acoustic glass uses polyvinyl butyral (PVB) interlayers that are specially designed for sound control. These act as acoustic membranes – they help to limit vibrations and, in doing so, reduce noise by as much as 50%.

You're not limited to one interlayer, either. Use more panes and more interlayers and the sound-reduction effect will be compounded.

PVB, incidentally, is also very transparent. This means you can keep adding interlayers without compromising the optical clarity of the glass.

3. An air gap absorbs sound

Sound-reducing glass is most effective when used in a double- or triple-glazing system.

This is because the air gap between the panes – like the glass itself and the PVB interlayers – helps to absorb sound waves and lessen noise.

Ideally, this gap will be filled with an inert gas such as krypton or argon. These gases are denser than air, so they're better at absorbing sound.

You can't just stick any old acoustic glass in a double-glazing unit and hope for the best, though. The two panes have to be of different thicknesses to work effectively.

Why? It gets technical – but we'll do our best.

Every object has a resonant frequency. If a sound wave of a matching frequency hits the object, it will cause the object to vibrate more forcefully – and loudly – than usual.

This is why opera singers can (in theory) break wine glasses when they hit the right high note. If the note matches the resonant frequency of the glass, it could vibrate it to the point that it loses structural integrity.

Two panes of equal size and thickness in a double-glazing unit are likely to have near-identical resonant frequencies. As one vibrates at its resonant frequency, the other will follow suit. This means that the glazing unit could, in fact, make certain sounds louder. Not good.

4. The framing system absorbs sound

Finally, the frame or sealed unit must be specially designed for acoustic glazing.

For one, it must be able to hold the thicker glass laminates that are necessary for sound control. Most traditional uPVC or wooden frames simply aren't designed to do this.

And, most importantly, the frame must hold that glass very firmly in place. If the glass is allowed to vibrate in its frame, its sound-reducing properties will be greatly diminished.

Final thoughts

To wrap up, let's go over what we've learned. Acoustic glass must:

- Be thicker than traditional glass panes

- Use a sound-reducing PVB interlayer

- Use a suitable framing system

- Take the form of double or triple glazing (if possible)

As you can see, several factors can affect the efficacy of acoustic glazing. It needs to be carefully specified and manufactured to guarantee an appropriate level of sound reduction.

But here at ToughGlaze, we're experts in acoustic glass – and our advanced glass processing facilities mean we can supply the right product for almost any use case.

Not only that but TG AG acoustic glazing can be combined with many of our other market-leading products. This means you can customise your glass to suit a wide range of practical, decorative or security applications.

Interested? Learn more about our sound-reducing glass – or get in touch with our experts to discuss your options in detail.