Glass edge strength and why it matters

Share this blog:

The strength of glass is determined by many factors. Find out the role glass edges play – and why it matters.

How strong is a piece of glass? This isn't a cunning riddle along the lines of "How long is a piece of string?" It's a practical question with practical implications for your building project.

Different types of glass have different overall levels of strength. A sheet of toughened glass (our speciality) is around five times as strong as a standard sheet of annealed glass. Laminated glass can be even more robust.

This strength comes from:

- The chemical composition of the glass

- The addition of protective interlayers

- The presence of compressive stress on the surface

- And yes – the strength of the edges

Manufacturers carry out strength tests to ensure their glass products are fit for purpose. Different methods are used, but what they all have in common is the application of stress to glass.

This could be anything from attacking the glass with an axe to firing a bullet at it. In the case of edge strength, however, manufacturers use a process called "four-point bending". This involves applying stress to the edges until they fracture. If they pass the test, they go to market.

It's obvious why glass strength matters – the safety of the building's users depends on it. But how about glass edge strength? Before we answer that question, let's delve a little deeper into the four-point bending method.

What is four-point bending?

Four-point bending is a way of measuring the edge strength of glass. At its most basic, it involves applying force at two points between two supports.

The process is outlined in detail in European standard EN1288-3. It's important to note that the following summary is no replacement for these guidelines. We hope, however, that it gives you a sense of the process.

How the process works

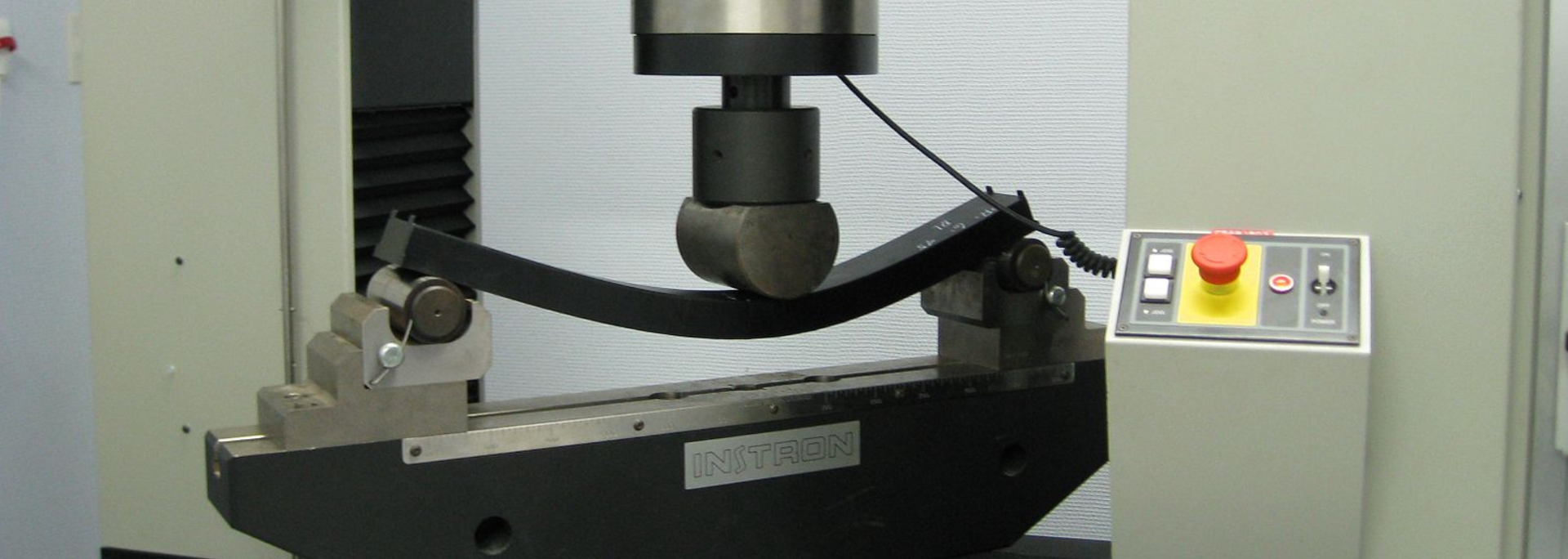

The four-point bending test is performed on a universal testing machine (UTM) – an electromechanical device that measures the mechanical properties of materials.

The glass is placed on two spaced-out support rollers. Two loading rollers then press on the glass from above. The downward force of the loading rollers is gradually increased between the loading points.

This continues until the glass fractures. Manufacturers then have a precise figure for the force required to break the glass.

Why does glass edge strength matter?

In one sense, the answer to this question is obvious. Edge strength is part of the overall strength of glass – and the stronger the glass, the safer the installation.

But glass edge strength is important in a more specific way, too. Edge flaws can lead to cracks and breakage. If the glass unit is strong but the edges are weak, you could be putting building users at risk.

Edges, in fact, are places where stress can concentrate. What's more, cracks and flaws on the edges are an inevitable byproduct of the cutting and manufacturing process. This means strength is needed to stop the edges from fracturing.

In some applications, toughened glass is required. This is a kind of safety glass that's far more robust than its annealed equivalents – and which shatters into smithereens, not dangerous shards.

Edge strength is an important part of the overall strength and safety of toughened glass. You need to make sure you're getting your toughened glass from a manufacturer or processor that provides strong, well-finished edges.

The same goes for laminated glass units. These are sometimes called for in commercial and high-load settings where the glass needs to withstand wind pressure or human loads. As with toughened glass, the strength of the edge is a critical part of the overall strength of the unit.

What other factors affect the strength of glass?

Edge strength isn't the only factor affecting the strength of glass, of course. Other factors include the chemical composition of the glass, any surface flaws and the presence of internal stresses created during the manufacturing process.

Toughened glass is made stronger by heating annealed glass at a high temperature and then rapidly cooling or "quenching" the product. This creates compressive stress on the surface and gives the glass its distinctive breakage pattern.

Laminated glass, meanwhile, is bolstered by a protective plastic interlayer. This means that when the glass finally breaks (something that requires a heck of a lot of force), the glass doesn't shatter but stays in its frame.

Is edge strength covered by building regulations?

Yes and no. Regulations and standards focus on the safety performance of glass. This is affected by edge strength, but regulations don't provide a specific edge-strength value.

The priority in building regulations and standards is that glass in so-called "critical locations" breaks safely and withstands force. Most of the time, this necessitates the installation of toughened glass, laminated glass or toughened and laminated glass.

H3: Does bevelling affect glass edge strength?

Glass edges can be polished or bevelled. This is often done to improve the appearance of a piece of glass and is often done for glass used in furniture, doors and tabletops.

It's not just a question of aesthetics, however. Bevelling and polishing also remove sharp edges and increase the overall durability of the glass by stopping stress from concentrating at the edges.

Bevelling can decrease resistance to impacts at some angles. But overall, bevelling and polishing methods add to the strength of the glass.

Can you polish toughened glass edges?

Yes, you can polish toughened glass. You need, however, to handle it with care. When toughened glass breaks, it shatters into lots of tiny pieces – and this can happen if you apply too much force to the edges.

In practice, this means that polishing toughened glass is a job for professionals with specialised equipment. While you can sand and smooth minor imperfections at home, professional edge polishing reveals expertise, experience and equipment.

Founded in 1993, ToughGlaze is one of the UK's most trusted toughened glass suppliers. For more guides and industry knowledge, head to our resource centre.