Toughened, laminated and heat-strengthened glass: what are the differences?

Share this blog:

Toughened, laminated and heat-strengthened glass: what are the differences? It's easy when you know the facts. Get them in our guide.

Glass is a bit like bread – everybody knows what it is. But when you look into it more closely, you're confronted with a bewildering range of types.

Shopping for glass can be like popping into a deli when all you want is sliced Kingsmill. Toughened, laminated, heat-strengthened… what, pray tell, is the difference? Isn't glass just… glass?

Well, yes and no. Most of the time you can just ask for glass for a specific purpose and your friendly glass-monger will get you sorted. But even so, it can be good to know the differences when embarking on a project.

In this blog post, we take a look at three types of glass which you'll definitely have encountered but might not know the names of. First up: toughened glass.

Toughened glass

Toughened glass is just what it sounds like: glass that's built to withstand knocks, bumps and scratches.

Let's put it this way: if Debbie Harry's heart had been made of toughened glass, she'd have had nothing to complain about.

Toughened glass is resistant to sun damage. Over time, heat can cause glass to expand or contract. This physical stress can sometimes lead to breakages – but not when you've used toughened glass for the job.

This strength is one reason why it's classed as a "safety glass". It's four to five times stronger than garden-variety annealed glass and three times stronger than heat-strengthened glass.

Toughened glass breaks in a particular way. Instead of breaking into jagged shards, it splits into harmless chunks about the size of a fingernail. This significantly reduces the risk of injury and makes it a doddle to clean up.

It's made by taking sheets of regular glass, exposing them to extreme heat and then cooling them rapidly. This method dates back to 19th century France – but the principle is at least as old as Prince Rupert of the Rhine.

In 1660, Prince Rupert produced teardrop-shaped pieces of glass by dropping molten glass into a bucket of water. This cooled it down rapidly. The resulting bit of glass could take a hammer blow – but if you even slightly damaged the tail end, it would shatter into smithereens.

Toughened glass can be customised. Most glass processors will offer frosting, colouring and other options.

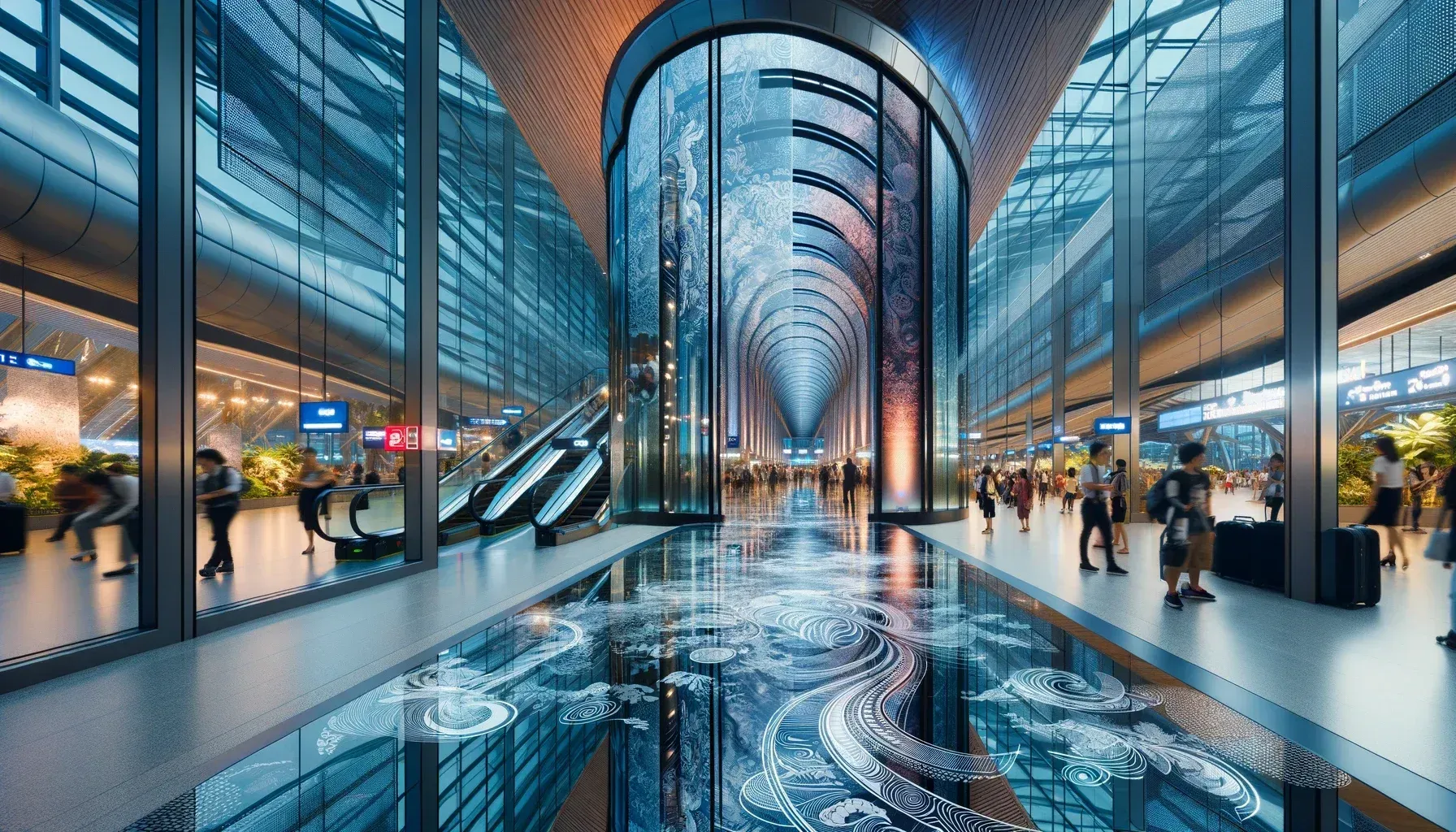

Even if you don't know the nomenclature, you'll have come across toughened glass in your daily life. It's used in a remarkable range of applications:

- Glass doors and windows

- Partition walls

- Tabletops

- Shelves

- Mobile phone screen protectors

- Kitchenware

- Passenger vehicle windows (but not windscreens)

- Shower doors

- Aquariums

- Diving masks

Laminated glass

Laminated glass and toughened glass are both robust but they're manufactured in different ways.

Laminated glass is sometimes known as "sandwich glass". This is because it consists of two sheets of glass bonded together with a polymer interlayer.

Ever seen a windscreen that's been given a beating? You'll see a "spider web" crack effect. This is thanks to laminated glass's sandwich design. It creates a surface that can withstand huge amounts of force.

It comes in different thicknesses and like any good sandwich can be constructed in different combinations and coatings.

Its robustness means it's also super-secure. The polymer interlayer makes it difficult to break into.

Laminated glass is low-emission. This is one reason why it gets used in lots of new-builds whose developers are prioritising thermal efficiency and sustainability. It's also great for reducing noise pollution.

Above all, it's safe. As well as being very strong, laminated glass is designed to remain in its frame even if broken, reducing the risk of injury or death.

Like all types of glass, it's available in a range of colours, tints and tones. It can even be put together with decorative interlayers, creating all sorts of exciting visual effects.

It's produced by sandwiching a plastic interlayer between two or more layers of glass. This interlayer can be polyvinyl butyral (PVB), thermoplastic polyurethane (TPU) or ethylene-vinyl acetate (cross-linked EVA).

Once the sandwich has been filled, it's passed through a series of rollers or vacuum bagging systems to eliminate any pockets of air. It's then bonded in the oven at an intense heat.

It's over a century old and only exists because of a laboratory accident. Édouard Bénédictus 12150 accidentally knocked a glass flask to the floor – but because it had been coated with cellulose nitrate, it shattered but didn't break into pieces.

Laminated glass was used for the lenses in gas masks during the First World War. Today, it's used for windows, doors, aquariums, display cabinets in jewellery stores, floors, stairs, skylights, windscreens and more.

Heat-strengthened glass

On the face of it, "heat-strengthened glass" is a confusing term. After all, aren't both toughened and laminated glass strengthened by heat?

Yes. And heat-strengthened glass is made in pretty much the same way as toughened glass. The difference is that heat-strengthened glass is cooled much more slowly.

On a scale of strength from low to high, heat-strengthened glass sits between annealed and toughened glass. It can withstand a heavy blow without shattering but not to the same extent as toughened glass.

Heat-strengthened glass, then, is tough but not toughened. It tends to be used for general glazing when a bit of extra strength is called for. It can also be used as a component in laminated glass – you can sometimes find this combination in roof panels.

Final thoughts

So there you have it – three types of glass that are used every day for safety and durability.

At ToughGlaze, we like to keep our customers in the loop, so make sure to check back in for more handy tips and guides.

ToughGlaze is a leading UK glass processor based in Bedford. We offer one of the widest selections of

toughened,

heat-strengthened and

laminated glass products available anywhere. For a quick quote, don't hesitate to get in touch.