When was toughened glass invented? The story of glass tempering

Share this blog:

Join us as we tell the fascinating story of toughened glass. It all started in a Roman glassblower's workshop…

You don't have to work in the glass industry to know about toughened glass. Today, it's used on everything from fire-resistant doors to smartphone screen protectors.

Sure, you're probably not

thinking

about toughened glass as you scroll through social media or tap out a text. But it's there – and you'd be worse off without it. Toughened glass is the magic material that keeps our iPhones intact, our bus shelters safe and our huge glass skyscrapers upright.

It wasn't always this way, though. Despite its modern-day ubiquity, toughened glass has only become seriously indispensable in the last century or so.

What took us so long? Start brewing a cuppa – this story is a doozy.

Prince Rupert's drops

Toughened glass is a bit like electricity. We discovered it before we knew what it

was.

Just as some Greek bloke was

conducting experiments with static electricity in 600 BC, so our 17th-century forbears were playing around with toughened glass in the form of disposable novelties.

These novelties were variously known as Batavian tears, Dutch tears or Prince Rupert's drops – named after Prince Rupert of the Rhine, who first brought these curiosities to the attention of the British court.

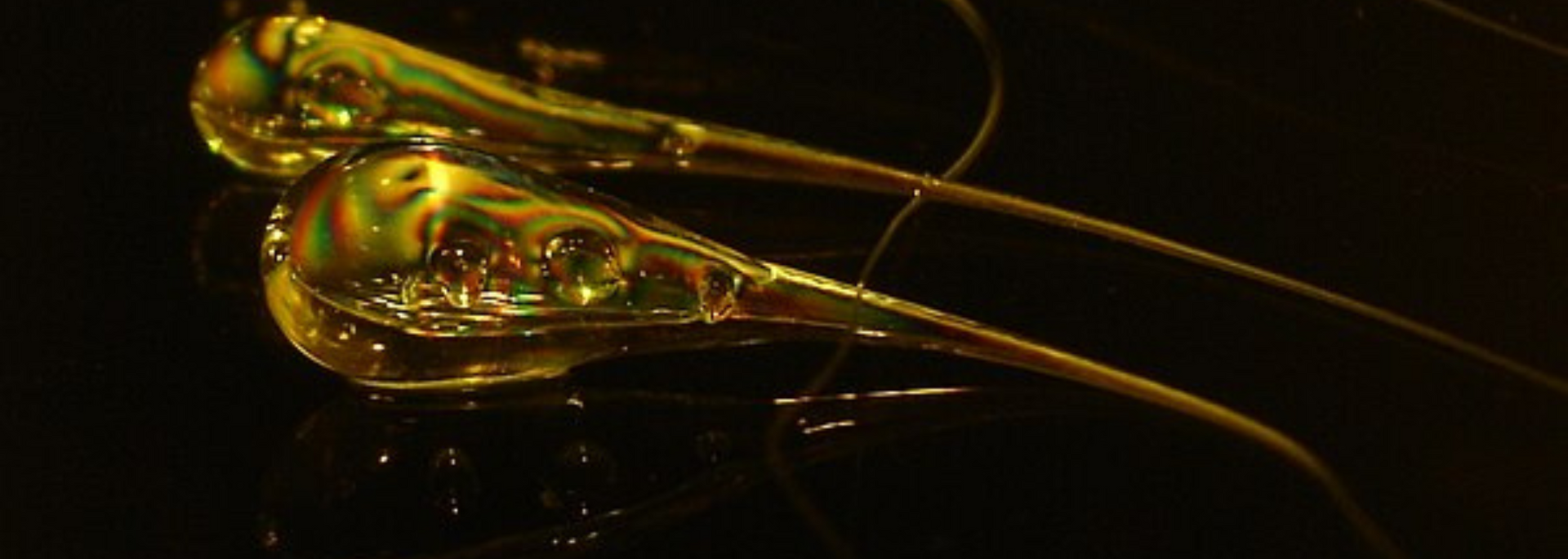

Prince Rupert's drops looked a little like teardrops or tadpoles. They were bulbous globs of glass that tapered off to a thin tail.

So far, so obvious waste product of the glass-making process. But Prince Rupert's drops didn't attract scientific attention because they looked like baby frogs – they did, in fact, conceal some curious secrets.

The bulbous end was as tough as old boots. You could give it a good thwack with a mallet and it would barely register the assault.

This alone was quite something. At a time when glass would shatter if you so much as sneered at it, a virtually indestructible glass object was a bona fide scientific wonder.

But it wasn't indestructible. Because if you snapped off the thin tail end, the whole thing would shatter into countless tiny pieces as if disappearing into thin air.

King Charles, the Royal Society and the Romans

As you might imagine, this party trick was quite astounding to 17th-century minds. It certainly astounded King Charles II, who – on witnessing the magic trick – called in the Royal Society to investigate.

The 17th century's top science boffins got together, pooled all their knowledge and resources and discovered what you've probably worked out already.

Prince Rupert's drops were merely globs of hot glass that had been rapidly cooled in cold water. In all likelihood, they were discovered by accident – and may have been common knowledge in the glass industry since Roman times.

You can imagine the discovery went something like this. A clumsy glassblower was puffing away, creating a vase or a pipe or an ornament. Clumsy as he was, he allowed a stray bit of molten glass to fall into a bucket at his feet.

That clumsy glassblower had inadvertently invented toughened glass. By taking very hot glass and quickly reducing its temperature, he changed the molecular structure of the material. The glass was now under stress – meaning it had become extremely strong but liable to shatter explosively if mishandled.

These properties weren't fully understood at the time, though. We'd have to wait until the 19th century until someone realised that the mechanism behind Prince Rupert's drops could have a practical purpose.

Francois Royer de la Bastie and the liquid tempering method

We only know three things about the life of Francois Barthelemy Alfred Royer de la Bastie. The first is that he had an incredible name. The second is that he was based in Paris. And the third is that he's credited with developing the first industrial glass tempering process.

Bastie's method involved heating glass until it almost reached its melting point, then quenching it in a bath of heated oil or grease.

The resulting material was much stronger than traditional glass – and, crucially, didn't need to be shaped like a tadpole.

It would be no exaggeration to call Bastie the father of modern glass tempering. Despite tweaks to the formula, we use a similar tempering process today.

Bastie first received a patent for his method in England in 1874. In a later US patent, he espouses the benefits of his new glass in no uncertain terms:

"Objects constructed in this manner will effectually resist violent shocks and the action of hot water, and even fire, and they are not liable to become chipped at the edges. It will be evident that this process can be applied to the manufacture of vessels ornamented in any desired manner."

Enterprising types took Bastie's invention and ran with it. Further processes and further patents followed – including, in 1877, a method that involved cooling the hot glass in moulds rather than oil.

The industrialisation of toughened glass

The 20th century was a time of rapid innovation. In 100 short years, the world managed to put a man on the moon, invent the microchip and revolutionise transport with fast, affordable automobiles.

And it was the rise of the car that transformed toughened glass manufacturing from a niche concern into an industry powerhouse.

When Bastie pioneered toughened glass in the late 1800s, he certainly wasn't thinking of car windscreens. As we can see from his 1886 American patent, he was primarily concerned with the manufacture of "articles for table service".

In fact, he dedicates a whole paragraph to describing how these articles could be decorated. They could, he says, be "coloured, gilded or coated with either metals of any desired colours, or designs or flowers may be printed thereon with vitreous colours", and so on.

But as cars took over our roads and toughened glass manufacturing developed, the burgeoning automobile industry started to take notice.

Henry Ford was among the first to use tempered glass in car production. In 1937, motivated by safety concerns, he

mandated the use of toughened glass for the side and rear windows of all Ford cars.

The front windscreens, incidentally, already used laminated glass. This form of safety glass was introduced in Ford's automobiles as early as 1919.

By the 1950s, toughened glass was commonplace in all American cars. Other industries soon picked up the baton. Architects, for instance, noted that toughened glass allowed for the construction of large, structurally sound glass buildings – and so the era of great glass skyscrapers began.

Toughened glass today

Nowadays, toughened glass and other forms of safety glass are everywhere. Their strength and safety properties mean they're more or less mandated in all new buildings in the UK.

But we travelled a long, long way to get here. Modern toughened glass would never have been possible without the work of clumsy Roman glassblowers, pioneering American automobile giants and one enterprising Frenchman who helped turn a party trick into an industry.

Here at ToughGlaze, we're proud to play our own small part in this fascinating story – and we can't wait to see where glass goes next.

Are you in the market for high-quality

toughened glass, cut to size? Here at ToughGlaze, we've been involved in some of the UK's most complex and renowned architectural projects. For a quick, competitive quote, don't hesitate to

get in touch.