Glass manufacturers vs glass processors: who does what?

Share this blog:

When customers buy glass, it's typically been processed as well as manufactured. Let's take a look at the role that manufacturers and processors play.

Who makes glass? You might think it's a simple question with a simple answer: a glassblower, maybe, or an industrial glass factory.

In fact, the glass-making process is split into two distinct stages. First, glass is manufactured. Your glass manufacturer makes big, off-the-shelf sheets. These are then toughened, cut and treated by glass processors.

The manufacturer, then, creates the raw material. The processor makes it usable for end users.

Here at ToughGlaze, we process float glass sold to us by manufacturers – so we know a thing or two about the process.

In this article, we take a closer look at the differing roles of glass manufacturers and glass processors.

Glass manufacturers

There are lots of different types of glass. The glass used to make a bottle, for instance, is different from that used to make a laboratory test tube.

However, most flat glass is something called "float glass". This is the material used for windows, partitions, glass floors, mirrors, touchscreens, windscreens and more.

It was pioneered in the 1950s by the British glass manufacturer Pilkington at its HQ in St Helen's, Merseyside. Before the Pilkington process, plate glass was made by blowing cylinders of glass, slicing them open and cutting them into panes.

The problem was that the sides of the pane then had to be polished – an expensive and time-consuming process. The Pilkington process circumvented this by floating molten glass over a bath of molten tin – no polishing required.

The other great advantage of float glass is that it can be shaped easily when heated. This is why it's the go-to material for windscreens, mirrors, furniture and more.

In the UK, there are three main float glass manufacturers: Guardian Glass UK, Pilkington (now a subsidiary of Japanese company NSG) and Saint-Gobain Building Glass.

Customers can buy sheet glass directly from glass manufacturers. Typically, however, their customers are glass processors who get the glass ready for market.

Glass processors

Whether you're buying glass for domestic or commercial use, you will more than likely buy glass that's been processed. This is a broad term that encompasses lots of different techniques.

1. Toughening

Toughened glass is the material used for glass doors and windows, partition walls, shower doors and more. It's a type of safety glass. When it breaks, it splits into harmless fingernail-sized chunks rather than jagged smithereens.

Glass processors toughen glass by exposing the panels to extreme heat and then rapidly cooling them. They can also customise the glass before it's toughened.

2. Laminating

Picture a car. The windows are made of toughened glass – but not the windscreen. That's because the front seats are the most vulnerable place to be in the event of a crash. The windscreen needs to be even more robust than the side windows.

Windscreens are made from

laminated glass: two sheets of glass with an interlayer. No matter how hard you bash a sheet of laminated glass, it will crack but not shatter, creating a "spider web" pattern.

Laminated glass is toughened glass with bells on. It's used for display cabinets in jewellery stores, safety screens in banks, glass floors and more.

3. Heat soak testing

Heat soak testing is a safety measure taken by glass processors to prevent the spontaneous breakage of toughened glass.

It's unusual for toughened glass to shatter without external force – but it can happen. This is often because of

nickel sulfide inclusions: imperfections that form in glass during the manufacturing process.

Heat soak testing involves placing panes of glass in a super-hot oven. If the glass breaks, it gets replaced.

Heat soak testing doesn't guarantee the detection of nickel sulfide inclusions. However, it does drastically lower the chances.

4. Cutting

Glass manufacturers produce large sheets of glass. A glass processor will cut them to size. This is an important service for glass installers who need to work according to the designs given to them by their clients.

5. Other kinds of strengthening

Some installations call for glass that's

fire-rated,

blast-resistant or

bullet-resistant. These techniques are all carried out by glass processors.

6. Designing

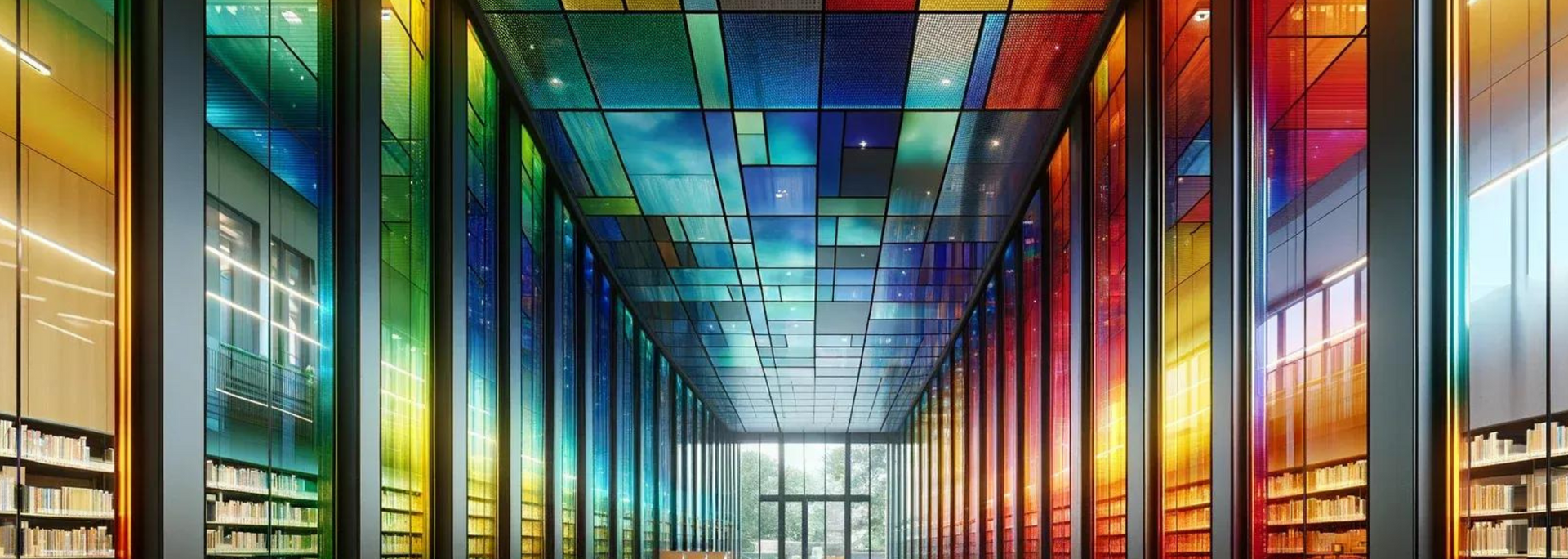

Glass has always been customised – just think of stained glass windows. However, today's glass is more customisable than ever. The options are so wide as to be a little daunting.

Companies sometimes want their glass to be emblazoned with their logo or other branding. This can be done with

digital printing or

sandblasting. Or they might want the glass to coordinate with the rest of the premises. This is where

coloured glass comes in.

Glass can be coloured in a number of ways. It can be achieved by including a coloured interlayer or interlayers, applying a coloured backing or introducing a pigment at the manufacturing stage.

7. Changing the level of transparency

Sometimes you want glass that's hard to see through – in a bathroom, for instance, or meeting room. This can be achieved through frosting – or, at the higher end of the market, through switchable smart glass. This is a type of

glass that can go from clear to opaque at the touch of a button.

8. Soundproofing

Glass processors can make glass soundproof by inserting an acoustic membrane that blocks sound. This type of glass can be invaluable in busy office environments as well as unique buildings such as recording studios.

Final thoughts

Here at ToughGlaze, we love getting glass ready to go. But we know that our job is only possible thanks to the work of glass manufacturers across the world.

Glass production is a complex system that involves many moving parts. Our role is to make sure you get the right materials for the job, every time.

ToughGlaze is one of the UK's leading suppliers of

toughened glass,

laminated glass and

decorative glass products. Feel free to

get in touch for a quick and competitive quote.